Description

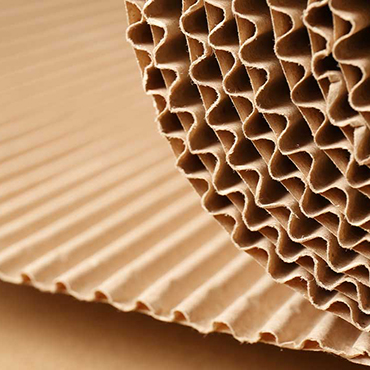

Flute paper is the middle layer of flute cardboard which can be used as a kind of protective packaging paper individually. Flute paper makes flexible support for protecting the product by filling the empty spaces between two outer protecting layers. Furthermore, as a substitute compatible with the environment and traditional packaging methods, including bubble plastics and other traditional plastic-based products, flute paper is made of a renewable resource and totally recyclable. Depending on your need, flute paper is available in various heights and weights and is generally supplied in the shape of a roll. Learn more about flute cardboard, its components, and its usage. How Flute paper affects everything, from packaging cost to its function in transportation? If you use packaging a lot, you are probably familiar with flute paper. Even if you don’t, you surely have faced flute paper in your daily life. Do you know the factors which designate how strong or how expensive the corrugated cardboard is? What is this paper made of? How can it impact the packaging quality and transition of your goods? This study aims to guide, explain, and clarify everything that can be important in this regard. Flute Cardboard Structure: Generally, a standard sheet of corrugated cardboard or flute consisted of three components; one corrugated or ” fluted” sheet is at the center, placed between two inner and outer lining layers. During the work, both sides of fluted cardboard are glued to the smooth paper or lining. The glue keeps the flutes fix in their positions and makes papers firm and constant. A picture of the flute and lining can be observed below. Raw Material and Composition of The Production: One of the fundamental elements that designate the cardboard properties is the type of the applied paper. The two main papers in this product as lining are known as Kraft and Testliner paper in the industry. Kraft paper is produced from softwood trees. They are one of the strongest and simplest kinds of paper for printing, due to the specific fibers within them. As a result, it is chosen as materials for producing the boxes and packaging. In fact, Testliner is a recyclable double-layer paper but not as strong as Kraft paper. Therefore, it’s usually used for the inner lining. It has fewer costs than Kraft paper too. However, regarding the popularity of Kraft and Testliner papers, there are other options for this product. Weight and Grammage: – 115/125 GSM – 140/150 GSM – 185/200 GSM – 300 GSM The flute also needs to be considered, in addition to weight, type, and number. In a basic layer, two linings are formed, in addition to the individual flute known as the “single-layer”. The picture below shows this subject. Furthermore, “double-layer” or “triple-layer” cardboard can be produced by adding an extra flute and lining. It significantly increases the strength and makes it appropriate for packaging heavier items, and in some cases, for more fragile or expensive items. Its picture can be seen below. Types of Corrugated Flutes: The type of flute is the last important factor about corrugated cardboard, which can affect its function (weight and cost). The flute is the corrugated part between two linings, and by altering its height and accordingly its size, different functions and characteristics can be achieved.

Reviews

There are no reviews yet.